I finally got around to make a leg vise and stand for carving lasts. This is only my first version, and I’m sure I’ll make some adjustments and refinements. But I wanted to type out my experience while it’s still fresh in mind.

I’m not yet sure whether I’ll prefer the leg vise, the stand, or both. So I decided to combine them, building the leg vise first, then building a stand to fit in the jaws of the vise, with a foot pedal to fit around the leg of it.

Inspirations

My most direct inspirations were:

the student benches at Lastmaker House in England

Don’t miss that this is palletized! Not terribly relevant for a one-man shop, but definitely a neat trick.

Nicholas Templeman’s bench, shared on Instagram here:

Nicholas was also kind enough to answer an e-mail from me about dimensions, especially for eventually mounting a stock knife.

Helge Baumeister’s stand, explained in this excellent video:

The similar cradles at one of Yin Hwa’s model rooms, shared here:

Basically, the “last vise” is a woodworker’s leg vise with some padding lining the jaws. The lastmaking stand or cradle works more like a shave horse, but with a strap rather than a pivoting wooden hold-down jaw.

Details and Lessons

I decided to use soft wood to start, for cost and so I wouldn’t hesitate to modify as I go. I’d hoped for kiln-dried wood, but my local lumber yard only had wetter Doug fir when I went. I decided to make do.

I used 1" hardwood dowel for the shaft of the foot pedal and the handle. I used 3/8" hardwood dowel for the locating and fulcrum pins of the last parallel guide. The hardware for mounting the vise to the bench is 1/4 carriage bolts, washers, and nuts.

The legs of the leg vise are from 2x4s. The stand was made in three laminated layers from a 2x6.

Good Idea: Taytools 775936 Vise Screw

It’s incredible how pricey some leg vise kits are. I went with this cheap import version of a simple Acme-thread screw and mounts. It worked well.

The 18" travel is far more than I need for lasts, or even soft wood utility work. But the way I mounted it, all that extra length’s hidden under my benchtop, right at the top where it doesn’t compete with much else for storage space.

The screw itself is 1+3/16″ in diameter, so I drilled 1+1/4" holes, and that worked well.

Good Idea: Double Up the Leg

I originally built the vise with a single 2x4 for the moving leg. It wasn’t long before I went back and doubled up the leg with another 2x4, glued and screwed together. I was afraid the extra weight might rack the screw, but that hasn’t proved an issue. The leg is now much stiffer.

Bad Idea: Parallel Guide Way Too Tight

I did a really rough job knocking out the mortises for the parallel guide at the bottom of the vise to run through. Even so, the tolerances were a bit tight, so I initially had problems where the guide would stick as I screwed the leg in and out.

I eventually went back and widened out both mortises, also checking with a square to make sure the parallel guide could slide freely when protruding straight out. That made a huge difference.

There’s a bit more rotational wobble in the moving leg now, but it firms up when clamped onto a work piece. The peg holes in the parallel guide still work fine for setting fulcrum.

Bad Idea: Hanger Hook for Fulcrum Pin

You’ll see in one of the photos that I originally set a hook into the side of the fixed leg to hand the dowel pin for setting the fulcrum on. That’s unnecessary, and puts a hook down by your foot, which is asking for trouble. Better just to store the pin in the narrowest parallel guide hole.

Bad Idea: Steep Foot Pedal Angle

One of the weaknesses of this combo is that the foot pedal for tensioning the strap for the stand can’t be right next to the bench, because that’s where the bottoms of the legs of the vise are. I worked with what I had and made something that works, but the angle of the foot board is uncomfortably steep. I’ll probably end up making some different pedal.

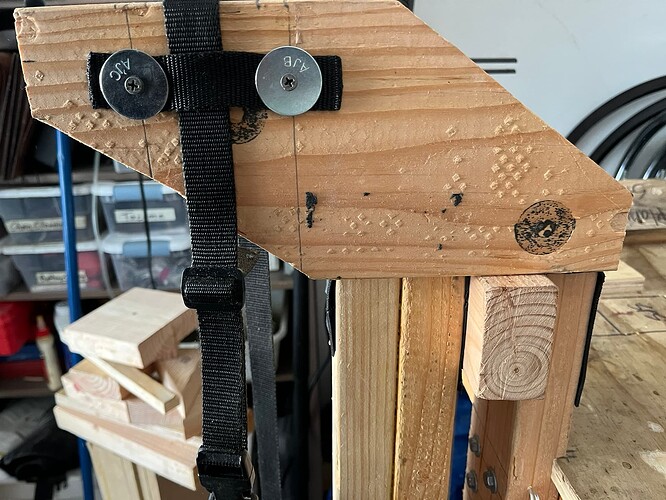

Good Idea: Align the Strap

I accidentally got the strap guides on the stand pretty well aligned with where the strap attached to the foot pedal when it’s all assembled. I’d have to redo it if those points where skewed too far.

Concerning: Stand Height

I put the jaws of the last vise at the working height I thought I would prefer. Putting the stand on top of that makes it rather taller. I might end up going back and shortening the stand, or rebuilding it to sit flush with the top of the vise jaws. It’s nice to have work close, for vision. But it might be tiring putting the necessary pressure on a Surform that high up.