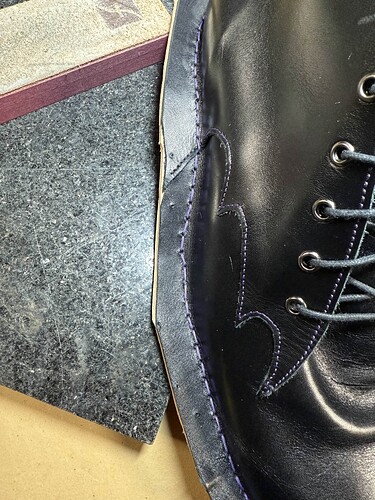

I guess I have a couple other things started and not finished, but this will be the third thing to actually get done (I say, intending to get the outsole and cuban heels on this week). First time doing a heel, or a stitchdown, or anything this high (MY GOD it was not a good time to have that much leg flopping around, and getting an anvil to set the speed hooks of the right size was a PITA and some are a little lopsided). Made for my best friend on the occasion of her birthday.

Woah! Big project!

What kind of speed hooks did you end up settling on? Can you share where you found the matching tooling, and how it’s worked for you?

I recently went through a similar process for slightly different hooks. I can vouch for how painful sourcing this kind of thing can be.

Also: Did you sew those uppers with a Speedy Stitcher? Even stitching down that way is pretty amazing. I believe they make slightly curved needles to fit, in addition to the usual straight ones. But they aren’t as easy to find.

I sewed the uppers partly on Deborah’s sewing machine, a postbed from I think Leather Machine Company? and on my Sailrite LSZ with the smooth foot and feed dogs. because the post bed has one roller and one needle, it makes it harder to go nicely over many layers/lumpy stuff compared to the walking foot Sailrite. Wish i did the backs with the Sailrite, oh well. I have one of those hand crank “Chinese shoe patcher” walking foot machines that works great if you can get the unusually small bobbins wound with proper tension, which is my problem…hence I still close shoes on Deborah’s post bed. Have you seen the little winding wheel they expect you to crank with the hand crank? Is there a trick to getting that consistent, or am I an unusually irregular cranker?

I’ll check on the hooks tomorrow, the anvil was one Deborah already had. The eyelets I have little hand dies and anvils to set with a hammer. I’d love a press type thing for consistent pressure the correct direction, but it seems hard or impossible to get the dies I would want for it?

Can’t say much about sewing machines, I’m afraid.

Three lessons I’ve learned:

-

Yes, a press makes getting good, consistent results a lot easier.

-

If you get a press, you really want to get a bunch of dies for it covering a variety of sizes, from the same seller, guaranteed to work with your press. Some of the presses use archaic threadings. Even if you choose a press that takes relatively simple, widely available tools, like tools on 3/8" shafts for set screw mounting, it can be hard to confirm whether tools in catalogs or listed online are actually that size.

-

While a lot of press tooling is machined for specific model numbers of hardware from specific manufacturers, like Moro in Italy or old USMC in the USA, it’s often possible to get good results setting with tooling for hardware that’s close to the same size. For example, several makers set USMC AA-size eyelets with tooling for Moro 051 eyelets.

For hardware you do sometimes, but not a lot of, it can make sense to just use a hand setter. It’s also possible to convert hand tools to press tooling by buying a cheap arbor press, then drilling and tapping a set screw hole in the arbor. But that is rather DIY, and tends to create a setup that’s hard to swap tools in and out of.

The Dream Machine, in my mind, is one of the old “Universal” hardware presses sold for shoe repair, with rotating turrets for selecting different top and bottom tools. These tend to come with a good selection of tool combinations for a broad variety of hardware. However, these aren’t manufactured anymore, and don’t come cheap.