@thenewreligion shared a few Instagram posts from yoshiken_shoemaking featuring a lap board with a slot cut out of the middle to allow the tops of boots to pass under. That inspired me to pull a lap board I’d made out of my junk pile and rework it with a slot and adjustable heel rests and toe cradle:

I’d previously built a lap board for shoes, without any cutout, for rewelting dress shoes. But I’d largely abandoned it, since all my original pairs and more recent repairs have been boots. I never thought about just cutting a big slot for the tops.

Construction

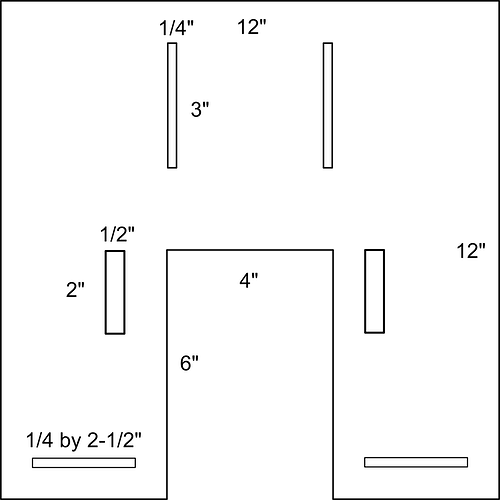

The core is a piece of plywood. The fixtures are from scrap 2x4s and a little hardwood board. The leather is no-name, chrome-tan pigskin from my scrap bin—the first thing I saw that seemed like enough and wouldn’t transfer color or lots of oils to the work. I fixed the leather to the fixtures with a light-duty staple gun. I don’t remember exactly, but I think the hardware is 10-24: one bolt, one washer, and one wingnut per slot.

The toe cradle is the same quick-and-dirty design that I used for my repair setup in the garage: two blocks of wood stood upright, their inside edges beveled, with a strap of leather suspended across like a hammock. The trick is to pull the leather high enough so that it doesn’t bottom out on the wood under weight and pressure of the shoe. Also to cut the leather to leave some slack, expecting to restaple a couple times to get it adjusted right.

The top slot here is 4" wide, which is wider than necessary. I wanted to avoid marring as much as I could, and also realized that the width didn’t matter so much if I can slide the adjustable heel rests closer.

Mistake: Distance from heel rests to toe cradle.

As it stands, the tops of the heel rests are about 6 inches from the bottom of the toe rest when the toe rest is slid down to its lower position. That’s still a bit long.

I’ll likely cut new slots for the heel rests two inches or more further up, closer to the toe cradle.

I misjudged this building the stand I use for repair in the garage, too.

Mistake: I’d like it even wider.

The lap board Yoshi uses in his posts is much narrower than this one, but I find I like a wider board, to get better bearing on my legs without holding them inward.

The board I made is 12 inches wide, because I wanted it to fit in one of the milk crates I use to store my shoe supplies. I’d like another two inches or so on each side.

Mistake: Just one bolt through each heel rest.

I can already tell that the heel rests are going to want to rotate around their bolts. If I made the rests longer and put two bolts through them, they’d take more time to adjust, but wouldn’t rotate. I suppose I could also go in there and glue a dowel or strip of wood to the bottoms for a similar effect.

Fine: Wingnuts on Bottom

I worried about having exposed wingnuts on the bottom of the board, since they could bump into my legs and knees. But it doesn’t seem like it’s going to be a problem.