Thanks so much!

First of all, I really appreciate your braoder thoughts on how patterning gets taught in cowboy boot world. I clearly guessed very wrong that it would be similar to what I’ve seen from other directions.

Making Last Forms

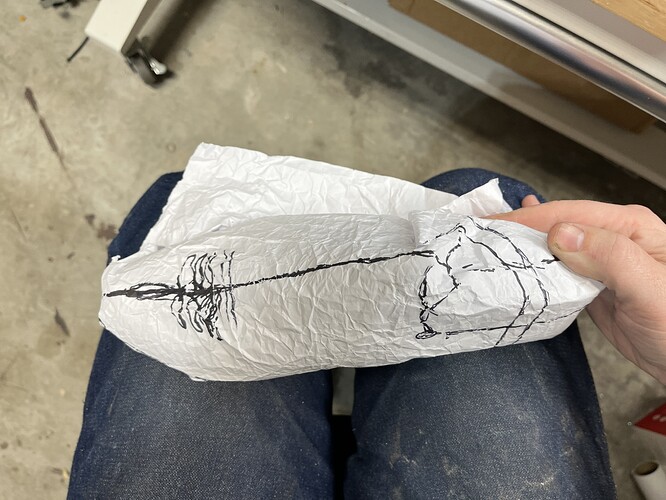

Thanks also for mentioning the crumpled paper method. I’d never seen or heard of that!

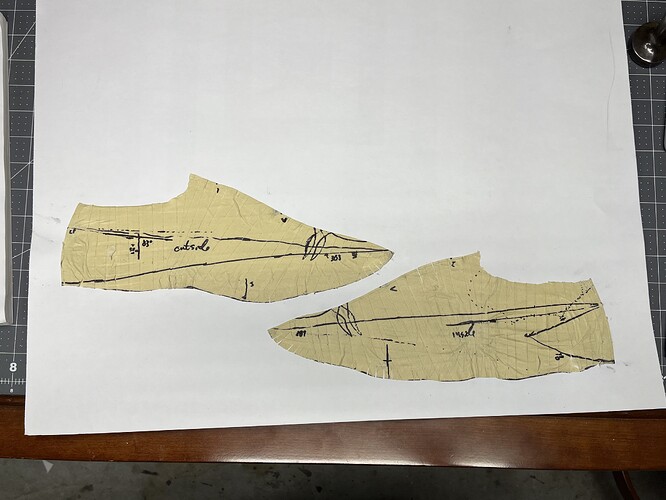

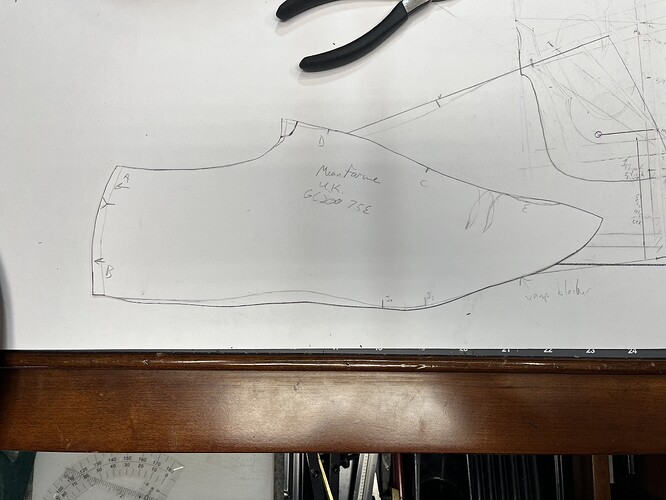

The technique I’ve seen, read about, and successfully used is exactly that: make slashes and allow the last form to splay out to lay flat. But make sure wherever possible to do that in lasting allowance, far away from any key design lines or seams. I’d try to keep the main axis, from the topline down the vamp, whole.

I’ve generally found that’s possible if I stick the tape peeled off the down first along a line through its middle, running roughly from the counter point to the toe point, then use fingers or tools to press down from that line out toward the edges. There’s not so much curve between that notional line and the main axis of the vamp or the topline of the backpart. There is a bunch of curve from that line down toward the featherline, so slashing becomes necessary to get it to lay flat.

There’s a level of refinement that I haven’t reached here yet: making sure toe caps end up in the right position along the main axis. I vaguely remember seeing in one of @Customboots’ videos that stitching bugs and wrinkles, and then lasting them right, can be tricky, both for a single boot and to make sure fellows match.

Aside: A Thanks

I hadn’t heard Anne’s name, either. Or seen her Instagram account.

Her post that you shared sent me on a little research jaunt, yielding several updates to shoemaking.wiki. I’ve made sure to reorganize so more general “making last forms” is in the process timeline, with taping and crumpled paper as techniques for doing that. I’d also never heard of the school that she mentioned, Arsutoria. I’ve now got at least an entry for that one, so it shows up in the list of schools with a little Italian flag.

Paper Mock-Ups

Maybe I can get you back for sharing Anne’s post by sharing another fun paper trick you may not have seen yet: making a mockup in brown paper, sewing it together with single lines, wetting it with a micro-mist spray bottle, and drafting it over the last with tacks to check pattern and design:

Or skipping right to the part where he sprays and fits over:

By the way, that video’s a pretty good video demo of last taping process, too:

I did this once with EVA foam, but that was rather expensive. Wetting thick paper makes a lot more sense.

I’ve been watching Terry’s videos for a while now. He recently started cutting his videos fast in some repetitive parts, like the last taping section above, showing the result of each repetition in rapid succession. He also did it the lasting section of that video, jump-cutting to the points where he sets each tack:

It turns into a rapid-fire thwack-thwack-thwack, but you can still where he chooses to put tacks in sequence and his process of splitting pleats.

Fast cutting usually makes my head hurt. But I actually enjoyed watching this new style. The way he does it, I actually find myself more eager to share as examples, since it makes for shorter, denser video. Hopefully you agree.