I already could stand to learn how to keep my stuff sharper…but I’ve seen folks on Youtube who all seem to have different types, including some that I would have assumed were for skiving. I have the Arford welt knife that Lisa Sorrel sells, but it felt like slow going and it wasn’t good for the initial carving. Honestly come to think of it I’m still finding a skiving knife I like that isn’t the safety curved one with replaceable blades. Can yall show me what you have settled on and why?

Holdfasts

Beware Tool Mania! You can carve holdfasts with a Stanley knife if you want!

Or a traditional, flat-bar shoe knife. This is one of my favorite shoe videos on the Internet:

I’m just a beginner, but I did the insoles for my last pair with a sub-$10 Hyde mill blade.

If you have an Arford Yankee-style welt knife, the guard on it can make some tasks easier. Ken Kataoka in Japan has a great video showing him use one as a feather plow as well as to gouge out the inside channel:

Sharpness is very important. I’ve never owned an Arford, and don’t know how sharp them come. But for each of my guarded blades—edge bevelers, French edgers, welt knives, feather plows—I cut a little strip of scrap leather the width of the cutting edge, glue down to a popsicle stick, rub on some green chromium oxide buffing compound, and use as a strop. Always be stropping.

There are still manufacturers of purpose-built feather plows, channel openers, and other specialized handwelting tools. Starko in Ukraine. TINA in Germany. Barnsley in England. I will neither confirm nor deny that I own any such tools. I’ll freely admit that I don’t need them. I’m not a maker in a bespoke shop, earning by piecework. I don’t have a boss or a production quota to meet.

Skiving

You mentioned a skiving knife. I think of that as a pretty different task from carving insoles: paring down the edges of pattern pieces at an angle, so they don’t bulge up when folded over or overlapped at seams.

My favorite knife specific for skiving is the one @customboots has made in Japan to sell. I believe mine is the 1" version, though I’ll be sorely tempted to add the ¾″ the next time I send in.

My Japanese leather knife is a very close second, and I think overall a more versatile knife. That’s the other style Ken uses in the video I linked above. Mine is one of the Craft Sha higher-grade ones with Hitachi “blue paper” steel. I believe the 39mm size. Someone keeps importing them to sell on Amazon.

Here’s Marcell Mrsan using a Japanese-style knife for skiving:

But again, Tool Mania. This is nine-tenths about practice and but a tenth about tools, a fact I am definitely repeating here for myself as much as anyone else. And here’s Tony Slinger again to prove it, in a video @customboots shot on a visit, doing it all with a shoe knife again:

The first time I watched that video, I did not understand how important his emphasis was. Show me how well honed your knife is, I’ll tell you how much you like skiving.

I don’t think Tony mentions the marble slab specifically. You really need a hard, smooth, flat surface to push against. The leather is squishy enough on its own.

Marcell Mrsan has some great videos showing how to use a scrap marble tile in your lap, so the scraps fall right to the floor:

I believe @Customboots recommended a marble Lazy Susan once, so you can quickly rotate the work piece around. Those are actually pretty cheap at Target, last I checked. And they can work double duty as turntables for photography and 3D scanning.

Yeah I have a chunk of thick marble (or something about an inch thick that could be a kitchen counter?) that I found around back of my old work, and I have the IKEA spinning cake stand thing. I also have a joint condition that makes some of the hand and wrist stuff specifically occasionally difficult. So it sounds like the best knife is the one I can keep sharpest, which for carving may be my trusty 9mm xacto to start? I’m not sure what it is for skiving…I can skant skive with the Japanese knife you mention (it’s my teacher’s), and I have a little stopping block that came with some gold compound and I do use that on my own blades. I had the Arford knife and a couple others I got from assorted places sharpened by a guy in my town. My teacher (Deborah Robertson) actually mentioned hearing recently that stropping it without compound on your jeans or other heavy fabric between most cuts is more helpful than just stropping it with compound more occasionally…I think maybe I need some books and video series only on blade edge maintenance and sharpening, gah! How do you even know what degree the blade is if it’s not a standardized kitchen knife type blade? I couldn’t find anywhere that would specify that, so I don’t know how I’m supposed to hold it at the precise angle to sharpen it on a whetstone or so.

“Always be stropping”

I want this on a t-shirt.

I’m glad that’s not stopping you! And I’m sure there are others out there who’d be glad to do an online search and find reports from you about what worked and didn’t.

I haven’t tried skiving with a craft blade. Let us know how it goes!

Dive deep into sharpening if you want! I have, but I kind of wish I hadn’t. It’s not nearly so complicated as all the sharpening supplies vendors and would-be gurus make it out to be.

It’s true that you can strop without any abrasive, just using leather or fabric to bend the grains along the edge back and forth, breaking off the loose ones. That is technically what “stropping” used to mean, while using an abrasive compound was “lapping” or “honing”. But I personally find chromium oxide works best for me, and works well for getting knives sharp as well as keeping them that way. It’s a bit of a shortcut, and maybe wears away blades slightly faster. But the stuff is cheap. I’m still working through the first bar that I bought, ages ago.

Does Notions and Findings have a merch section? I’m always tempted by the Maine Thread shirts, and will probably succumb when they come out with their new designs.

I always thought D.B. Gurney shirts, done up like the boxes in blue ink over heather brown, would be a trade-show hit.

By the way, I hadn’t seen Deborah’s name before. I’ve added an entry for her as a maker, a teacher, and a school to my notes. People seem to especially appreciate the entries that index teachers and schools.

I played around with having t-shirts for a while, but it’s expensive and you never seem to have the size someone wants. I’ve done print on demand shirts with no response so I finally gave up. Now I just make them for myself, for my own amusement.

It’s a theme around here!

On the other hand we’ve got your stickers stuck up everywhere. The girls put one on the washing machine for some reason?? ![]()

For skiving knives, they are supposed to be a Very acute point, so when you’re sharpening them that is using some sort of abrasive to actually remove material and set the angle of the bevel. I think 15degrees if you really want a number, double beveled. You can just drop your hand as low as reasonably possible and I just use the thickness of my finger as a rough guide, but like Tony says if you keep that edge stropped frequently, between every piece, it’s pretty rare that you have to Actually, go back and sharpen a new bevel onto it. Leather will soften the edge, but not really take chunks out of it.usually. Frommer said chrome tan has chunks of chrome metal that was all the edge faster.

I really do love those Japanese skiving knives that Lisa has. It makes it very easy in my opinion to get the right angle and control the skive. I gave one to my boot teacher and he liked it so much that’s what he uses now.

You’re welcome. ![]()

@Customboots, can I ask you about the “Lisa” knife that Barnsley offers?:

How does it compare to the knives from Japan?

I hadn’t seen this!! It looks great!

I requested that they make a knife like this and sent them the specs. There was resistance at first to making it a double bevel – double beveled knives are almost unheard of in European shoe making. I only saw the first prototype, with a single bevel. I talked to Bill and asked him to explain to them why it was so important, and please make it double beveled, and I didn’t follow through and see if they ever did it.

If they based it on the knife Bill made and took to them (which he made following my exact specifications) then it should be just like the Japanese skiving knives I sell.

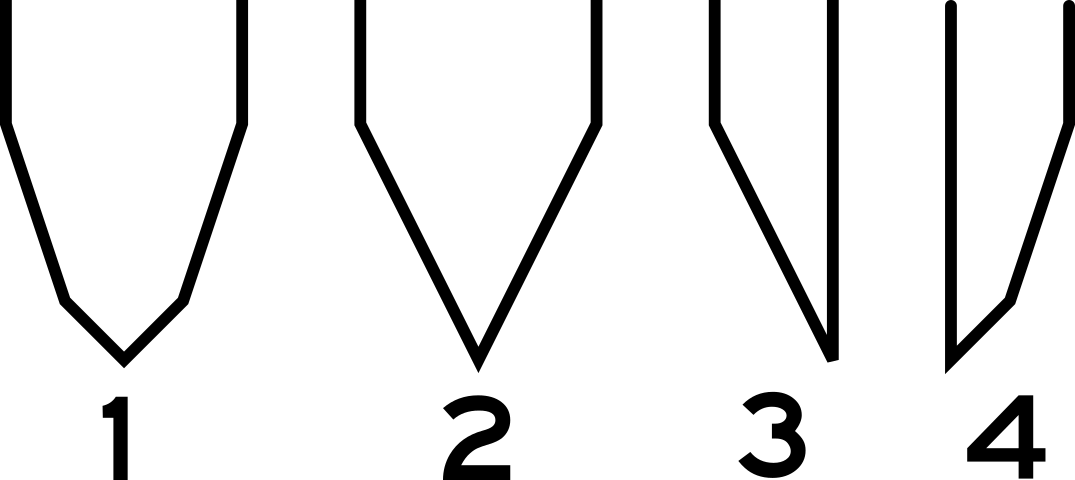

By double-bevel do you mean that there’s a larger primary and then a smaller secondary bevel on each side of the blade? So number 1 below:

I did go and look at the knife I got from you, but I’ve stropped it so much it’s essentially convex now. If there was a visible line between primary and secondary, it’s gone now.

Either way, can I ask why you prefer that shape? I’m definitely coming up blank trying to think of other examples from Europe.

I’ve generally leaned toward blades sharpened on just one side, since they’re quicker to strop and I feel like I’m better able to keep cuts flat when I’m carving. I’d really rather use my Japanese leather knife—number 3 above—to cut a flap for closed outseam channel, for example. But when I’m skiving against marble or glass I reach for The Lisa Knife.

Like #1

A double bevel knife is perfect for inlay/overlay work. Other than right and left hand, there are two main ways to skive – Push Skiving, which is pushing the knife away from you, and Pull Skiving, which is pulling the knife toward you. The shoe makers I’ve seen rarely ever do both. They typically Pull Skive and they’ll even start on a corner by angling the knife as they begin so the leather doesn’t wrinkle up as they begin. BUT, they’re usually working with a leather such as calf, which is firmer and heavier than kangaroo, and offhand I can’t think of any extreme angles on a shoe quarter. On the other hand, I’m doing incredibly intricate inlay/overlay work, using kangaroo leather, and often the design features very long skinny points. For this type of work, you must be able to both push and pull skive to reach all of the corners. Also, for this type of work, it often takes me three to four hours to skive a set of boot tops. The last thing I want is to have to pick up one knife, use it, put it down, pick up the other one, use it, put it down, pick up the other one… for hours. I need to be able to flip my knife over and back and over and back and over and back so I can both push and pull skive.

Also, if the secondary angle is gone on your knife and you basically just have a sharpened edge back on the full thickness of the steel, your knife is going to slip out of the leather when you try to skive. That thinness leading up the sharpened edge is also crucial so you can glide into the leather as you skive.

@Customboots do you have a quick blurb about when you’d recommend your three-quarter-inch skiving knife, rather than the one-inch version?

I’ve got the 1-inch version, but find myself pining for an even thinner push knife, albeit not so much for skiving work as for other jobs. When skiving uppers, I often find I want more blade width than width to skive, so I can run the tip of the blade against the marble or glass a few millimeters past the edge of the leather, to avoid skiving past zero and leaving a ragged edge.

I haven’t done any inlay and don’t know a lick about it. I’ve been doing lots of seam and fold allowances instead.

Still love the knife. Used it plenty on my current pair!

Yes, I find the 3/4" knife more comfortable and functional for long hours of narrow skiving, but since the 1" knife will do both very narrow skiving AND wide skiving, that’s the one I recommend if someone’s trying to save money and only buy one knife.

Well, after looking at everyone else’s strop vs mine, i got some Flitz and green compound, added some leather conditioner to my stop first, and coating it much more thoroughly. Now all my knives are ACTUALLY sharp, I can long skive with a normal blade again, and even use it to trim an insole. Looks like the Ukranian blacksmith I got these from is no longer on Etsy, but I like these knives. The C S Osborne push skiver is nice for straight lines and the angle you hold it at feels a little nicer on my wrist. Also pictured, one of my little silicone glue spreaders. Thanks for the tips! I’m probably gonna spring for Lisa’s 3/4" knife though, as the shape of the knife I have now is a little odd and large.

Congrats on a big leap forward!

I suppose it’s technically no longer just stropping when you add an abrasive to the leather. Some kind of polishing, I guess. Not that anyone should care in the least. Sharp knives!

I’m glad you’re enjoying that Osborne skiving knife. I bought one and was really looking forward to it, but never developed a knack. I’ve still got it listed for sale here on the forum.