Yeah the basswood seems softer, in that it was easier to indent with my thumbnail. I wondered if it would hold up to hammering but in my extremely unscientific opinion it took about as much force without warping as the birch. When i hammered it more after getting down to the tabletop it splintered off similarly too. Interestingly the basswood pegs look noticeably fatter after being driven in than the birch (it starts 3 thousandths of an inch bigger at 3/32” rather than 1/11” but i mean same size to my naked eye) so softness may run both ways, more compressible may mean that the driving actually makes them expand more within the hole. Also might mean theyre easier to work loose?

Just tried pointing some basswood by hand with a knife. Sure is easy to cut!

I frankly don’t feel safe even trying to reason about these things. At least not yet.

I’d really like to hear from some repairers, and specifically about pegs that failed.

https://patents.google.com/patent/US281A/en

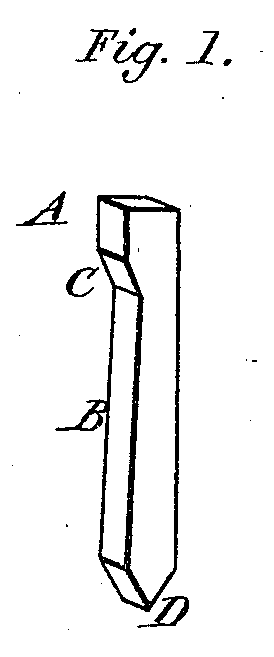

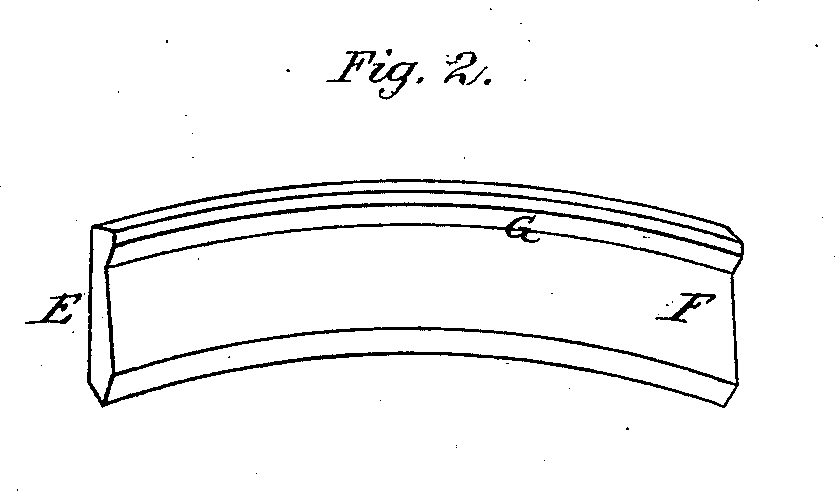

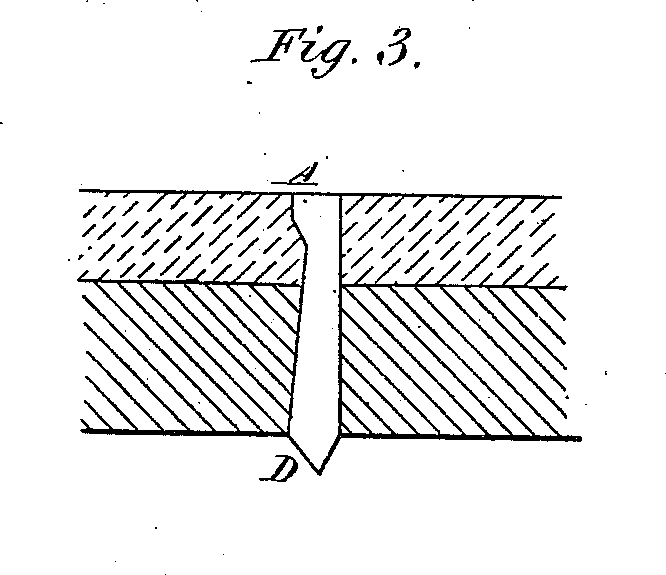

US patent number 281, apparatus for making pegs

7 posts were split to a new topic: Kearsage Peg Company

A bootmaker on the FB forum i follow says he keeps maple and oak peg strips ready for making pegs with, he said he learned to do that from his grandfather.

I haven’t given up on DIY pegmaking. Just waiting on a new tool I think might help. I believe it’s one of these:

Basically it’s a tiny 90-degree chisel-like jobber with a push handle, for wood carvers. If it works well and I got the right size, I’m hoping I can mark a grid on end grain, score some lines with a craft blade or razor saw, gouge them out into little v-shaped troughs with the v-tool lengthwise and crosswise, then split along the grain for pegs.

@Customboots was kind enough to report that my initial batch of maple pegs don’t look hideously irregular compared to the imports. But I set out to make 6/11 soling pegs and ended up with more like 7/9 heeling pegs. I’ll try drawing the grid for the points a little finer next time.

Digging around old patents, I found an interesting twist on the shapes of pegs:

https://patents.google.com/patent/US148575A/en

Why not put little notches in them to held them lock in place?

If we’re making our own, there’s nothing stopping us from doing this.

Here is a very interesting page listing Diamond round/square toothpicks for sale as wood pegs!

https://www.shakerovalbox.com/online-store-1/Wood-Pegs-aka-toothpicks-p49526341

The “product description” includes a neat tip:

Tip: Cut the box in half on a band saw to create pegs. Be sure to hold box down securely when cutting.

I have a box of these coming Thursday.

Oh now that’s really cool. As much as i enjoy the tedious parts of this pursuit, the peg making can stand for a few efficiencies like this ![]()

Interesting seems like you’d need a plane of some kind to create that profile

My experience with a Flexcut-brand v-tool cutter has proved only partly successful:

It’s possible to mark a grid and cut v-shaped grooves along the lines with this tool. It’s possible to split along the grooves of the grid—a dull rather than chisel-sharp splitter is best. But overall, it’s not quite neat and easy enough that I’d want to do it again.

For one, the bottom of the point of the tool I received has a kind of curved lip to it. It’s not two straight blades meeting nicely at a 90° point. That said, once you get the cut started, it’s fine. It really helps to score the line before starting the cut.

However, the greater problem has been the 90-degree shape. Even cutting down to a depth of a couple millimeters, the points created by crisscrossing aren’t as long as I’d like.

I’m going to give the concept another try with a slightly different shaped tool, this time a 60-degree v-cut rather than a 90-degree. I’m hoping that’s a bit easier to get started in scored lines and also creates longer-tapered points.

Paul “Peg” Pillsbury History

Thomson’s The Path to Mechanized Shoe Production in the United States gives a capsule summary of a pegmaking pioneer starting on page 41. The passage cites Shoe and Leather Reporter 11 of July 16, 1868, but I couldn’t find scans of that particular issue online.

- born near Newburyport, Mass.

- worked as a mechanic making wind and water mills, farmed, and invented a corn sheller and bark mill for tanning production

- shoemaker approached him to build a heel peg machine

- generalized from heel attaching to bottoming as a whole

-

To make pegs, he “plowed and cross-plowed” a piece of maple to form the points, split it into combs and then into pegs.

- focused on manufacturing pegs rather than shoes

- built own forge, lathe, and foundry

- opened a peg mill in 1815

- became known as “Peg Pillsbury”

- selling pegs spread knowledge of pegged construction