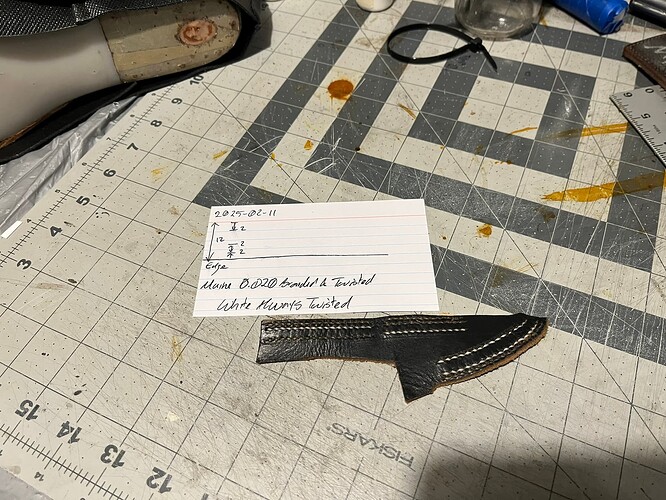

Good Idea: Keep doing studies on scraps before committing.

I’m going forward with a somewhat simpler hand stitch than I usually like for the quarter seams: three rows of slanted saddle in two colors.

I’m still not able to guess which stitch and color combinations will look good over black as opposed to brown or tan. The lighter base colors afford more chance for contrast between different thread colors, like black and white, while it’s easy for darker colors to fade into black background.

Spacing 3mm. I settled on Maine Thread 0.020" braided white and ochre. Some of the lines in the study photographed are using 0.020" twisted or 4-cord linen instead.

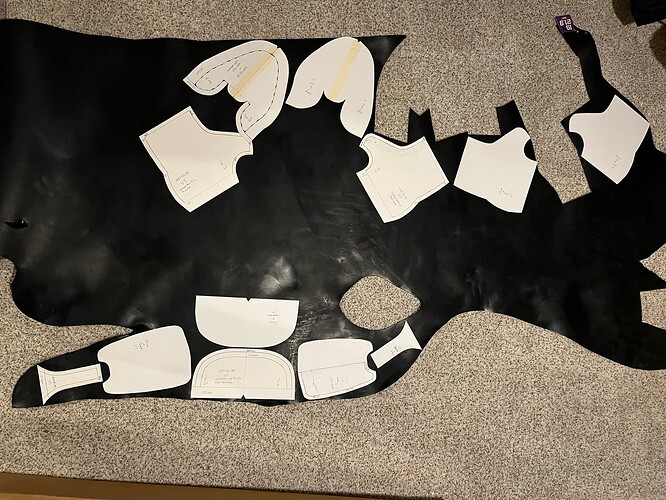

Good Idea: Cut mirrors of pattern pieces to lay out for clicking.

This isn’t exactly the layout I went with, but it’s close.

Especially with the inside-outside asymmetric pattern this time, it was nice to have a piece of paper to lay out and trace for every part I wanted to click.

Backseams

This is Maine Thread 0.040 twisted black thread on 5 mm center-to-center hole spacing. OKA Factory pricking iron and awl.

The acute points and straight shanks of the OKA awls makes it really easy to get consistent holes, at the price of making it harder to minimize the size of the hole by adjusting depth when you want to. I can see how the OKA style makes more sense for wallets, bags, watch straps, and other leathercraft-type projects.

Bad Idea: Gluing backseams together too well.

It makes sense to fix the quarters together and then pierce holes for the backseam through both at the same time. However, I did Aquilim 315 here, and let them cure. That made peeling the flaps past the backseam back to hammer down more difficult.

Next time maybe basting tape.

Starting to close.

This is 0.020" Maine Thread braided, ochre color, on 3mm center-to-center spacing. OKA Factory pricking irons and awl again. It’s so nice having irons in both normal and reverse.

These will have heel counter covers, as well. I’ve holed them, so they’re ready to sew on.

Good Idea: Use a French-style saddler’s clam.

I documented my DIY build from an IKEA stool here on the forum.

I’m definitely racking up a list of small modifications I’d like to make, but overall it’s been a joy to use.

Bad Idea: Not double checking original pattern lines to be folded over.

I ended up with backstraps of slightly different widths. It’s barely noticeable, but they are slightly different.

I suspect this came about from distortion to my pattern piece lines after skiving. I probably should have clicked for these pieces oversize, skived, and then cut to intended shape.

Bad Idea: Some hole layout mistakes.

One of the backstraps has one more stitch hole in each direction, toward the inside and toward the outside, than the other. I think this is partly due to the shape distortion and partly just a mistake I made with the iron. I should have fudged it to make them more symmetrical.

On one of the quarters, I also started pricking holes from the backseam, rather than from the from of the top band. This led to a hole at the front of the topband, where the stitchline takes the turn down the facing, that is not spaced evenly with the rest.

Lesson learned, I started pricking holes on all the other quarters from the front, rather than the backseam. Let any irregularity fall under the backstraps. There’s weird stacking going on there with the flattened backseam and all the overlapping pieces, anyway.

These aren’t done yet. I haven’t even drawn in the waist lines yet. But I wanted to get down that I’m using Keystone insole leather this time. I believe I got these from @customboots as “Heavy XLarge Insoles”.

I’ll be handwelting so I’ll see how that goes.