Foam and Paper Pattern Proof

I decided to do another mock-up with foam shelf liner. I’m using Con-Tact Grip “Premium Black Non-Adhesive Shelf Liner” again, this time in black for upper and white for lining.

Here’s the fully assembled mock-up over the last, on its side. The lines at bottom mark lasting margin.

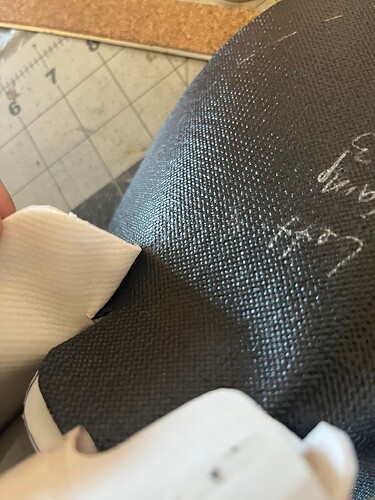

Oh, basting tape, how many ways are there to love you? I got a couple rolls of ¼- and ⅛-inch tape a while back, I believe as an add-of to a Springfield Leather order for some belt parts, and have really enjoyed using it since. It can be a little fiddly peeling the backing off, but from there, I’ve been really impressed with the adhesion on leather, foam, and even paper. It’s definitely more expensive than liquid glue, but well worth it for me.

Here I’m lifting up the upper pieces to show part of the lining seam beneath. Per the Seidich’s descriptions, the two seams meet and only slightly underlap at a “fitting point” under the quarter tabs, just behind where the stay stitches will eventually run.

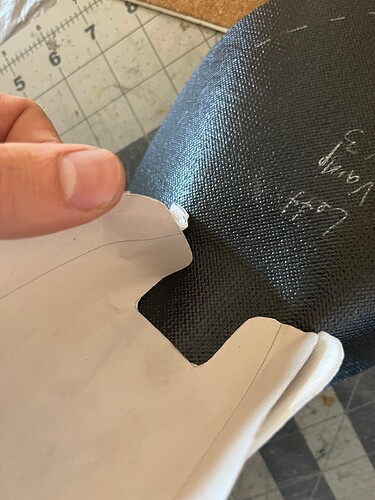

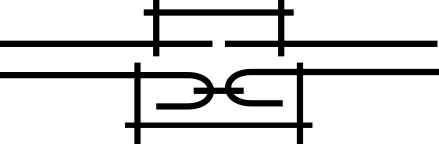

Here’s a closeup shot of the slitted tabs, which the Seidiches call “Derby noses” or “lining noses”, that pass up through slits the vamp lining, then through the curves on the sides of the tongue tab on the vamp, then under the quarter tabs to line them down to the stay stitches.

I originally patterned these “noses” to go all the way down to the bottoms of the quarter tabs, lining them completely with some trim margin. I’ve since revised my patterns to better track the Seidiches’ example, stopping the noses under the stay stitches. This did indeed allow me to baste the upper and lining together separately, then bring them together without “breaking” the upper quarter seams to slip the “noses” under.

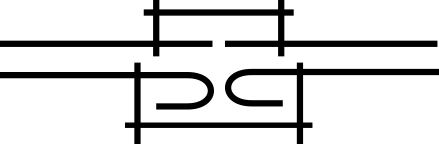

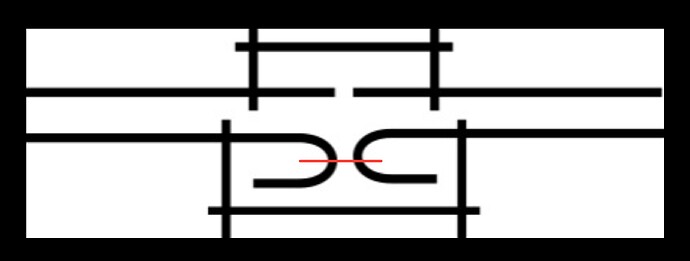

I also decided to try a backseam style inspired by one @thenewreligion shared elsewhere, courtesy of Mikhail Bliskavka of Arno.

Basically:

- The back edges of the quarter linings are patterned without any allowance. Rather, they’re butted together.

- A roughly inch-wide heel slide gets laid and topstitched over the lining seam, facing the back of the foot and leg.

- I added about 10mm of allowance to the backseam of the quarter panels themselves. The plan there is to sew together back-to-back, then turn the allowance back and beat it down.

- A backstrap covers the outside of the backseam from the topline down to just a bit below the top of the heel counter cover.

- Unlike @thenewreligion’s example and the Arno boots I’ve seen, my quarters continue all the way down to the featherline, underlaying the heel counter cover. I’m planning to sew the heel counter between the upper and heel counter cover.

For mocking up, I lay the backs of the quarter panels flat, then used a flat-clinch office staplers to hold them together, along the line marked for the seam allowance. I then stuck thin strips of basting tape to the edges of the flaps and pressed them down. A whole lot easier than doing it in leather! No hammering required.

I did the mock-up gusset tongue out of paper, rather than foam. I think that was a mistake. All I could really do a for a fit test here is tape the bottom of the tongue around the tab and check that the “wings” to either side of it roughly matched the vamp and quarter tabs.