I’d never have thought of that. Are those stones for watchmaking?

Any sort of fine metal work. Watch parts, gun parts, knife parts, etc, will often see it done.

Gives a smoother, more consistent finish

Looking good.

The more I think about upper patterns with fewer but fancier stitch lines, the more I like the concept.

It’s one of those things that is more subtle from a distance but adds a lot of interesting details up close.

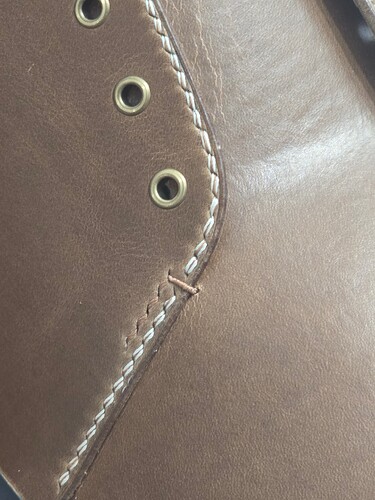

Uppers felt like they needed a little extra reinforcement at the upper opening so I added a single crossover stitch. Looped through the holes twice, then wrapped a dozen or so times before tying off.

With that, uppers are ready to go

Using 7oz Horween vegtan horse butt for the insoles. Thinner since they won’t get a welt.

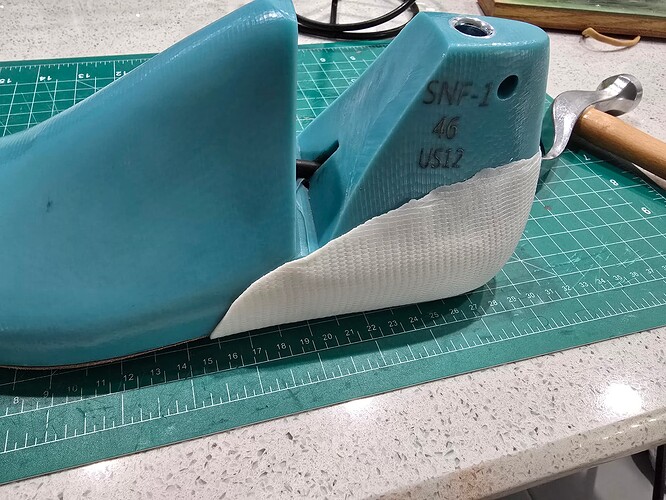

I saw a recommendation somewhere to use “vet wrap” as an alternative to bicycle tires when insole molding. So far, it works great and is nice and cheap. Will see when I open up the christmas present if I still feel the same way.

Looks like the kind of bandage you get after donating blood! If so, I imagine it conforms to the curves very nicely, but might not last as long or give as much tension as bike tires.

I’ve been using old bike tires for a small handful of pairs now. I like how it stretches, but I do see the ends slowly fraying away as I drive more and more tacks through.

I was taught to use Ace wrap and I’ve been using wide elastic and that’s also fine. But I tack the ends of the elastics, so a wrap that sticks to itself is more convenient.

Same idea. Seems like it may be slightly stickier, but pretty much it.

Started the heel counter using some of the thermoplastic reinforcement material… man, how are you supposed to skive this stuff?

Gave up and made the counter out of the thinner side of the horsebutt I used for the insoles.

I haven’t done much research on thermoplastic stiffeners, but I don’t think I’ve seen any references to skiving thermoplastic heel counters. I don’t think any of the thermo heel counters in factory boots I’ve taken down have been skived, either.

Just thinking freely, it might be possible to heat the edges and press of hammer to a taper.

I have definitely seen reference to it being skived, but it does not work nicely. The stuff i have is about 1mm thick, so definitely would leave an edge if i don’t do something. I have them cut already, so once the leather ones finished drying, I will give it a go with trying to hammer it down or something.

You are correct on being able to use the hammer to feather out the edges… as long as the reinforcement is fully supported. Having it span across the hinge in the last is problematic.

I test fit the counters I had drying last night and I am not a fan. My pattern was off so they sit too low. Also, the leather is too stiff.

I found a great video series last night discussing the mechanics of stiffners as they relate to your foot and remade mine. https://youtube.com/playlist?list=PL7VzDraQKY1dSIw3CcWtnvdRJEjPdDzub&si=b2ADSoQbCw4OQ8yf

Still using horsebutt, but a thinner, tumbled one that’s a bit more pliable. That with then new pattern has these looking much better.

Bill Bird’s series is a great reference. My notes are here:

One detail I still don’t quite understand is why he recommended skiving the top edge from the flesh side and the bottom edge from the grain/hair side. I don’t think he does or mentions that in the other video tutorials he’s shared on YouTube.

So i skived that way when I made round 2 of the stiffners and it makes sense to me. On the upper feather edge, you’re skiving the side against the lining, so you get the smoothest surface facing out. Least chance of something printing through. On the feather edge side, you’re leaving the bending surface against the feather edge, giving the sharpest crease.

I definitely struggled with doing the “scooping” skive on the feather edge he discussed. I actuallu went as far as funning a grooving tool along the feather edge bend line/lasting allowance line to help force the bend there.

His lasting videos are great too. Definitely gave me a better understanding of the order of nail placement.

Looking good so far

Still need to finish filling in the sole, but have one foot nailed, so good chance to take some photos looking more finished.

Did use the thermoplastic tow puff material I have. Nice and easy to work with.

Annoyingly, this chromexcel creases like crazy when you fold the toe up to do the front lining/toe puff.

Was able to get it pretty well back to normal with some conditioner and judicious rubbing with a bone folder.

Hmm, thank wrinkling is annoying.

I’ve had really different experiences with Chromexcel. Granted, I’ve nearly always bought “craft grade”. But some of those hides were clearly marked down for grain issues, while others had obvious defects in otherwise outstanding material.

Trying to be more helpful now, two ideas came to mind:

- Wet the vamp before peeling it up.

- Stop heel and shank lasting further back behind the balls. I can see myself wanting to last a lace-to-toe-ish pair like this right up to the tabs of the quarters, but I think that might require more of a sharp flip-up for the toe puff.

It’s probably a bit of loose grain in that section of the hide that isn’t helping things too. I have the first upper that I sewed together sitting here and I can crease it like crazy without getting any lasting marks. I know chromexcel has a bit of a reputation for getting some loose grain sometimes. This hide is one of the horween seconds from Maverick, so could definitely be a factor.

I still need to do the second shoe, so I will wet it a bit before pulling to see if it helps at all (or maybe helps them come out a bit with some working?)

I’ve definitely worked Chromexcel with loose grain, but it was marked and sold as craft grade. My hot take on the “Chromexcel lottery” among enthusiasts is that I strongly suspect it’s unfair to Horween. It’s up to Horween what they ship, but it’s up for manufacturers to sort and click right. Some manufacturers seem to “win” a lot more than others.

As for us pipsqueak small-timers, given the industry demand on Chromexcel in recent days, I assume pretty much every hide sold retail was passed over.