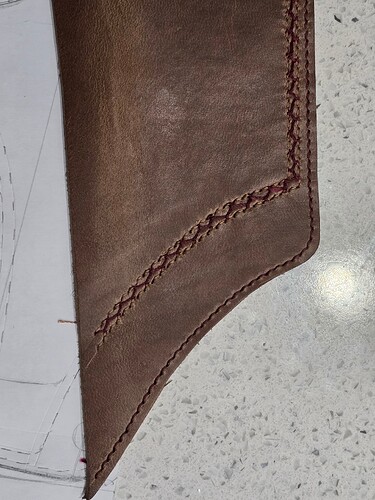

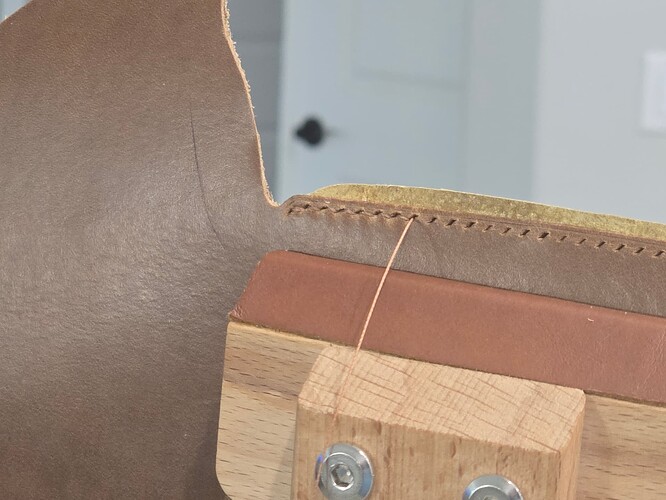

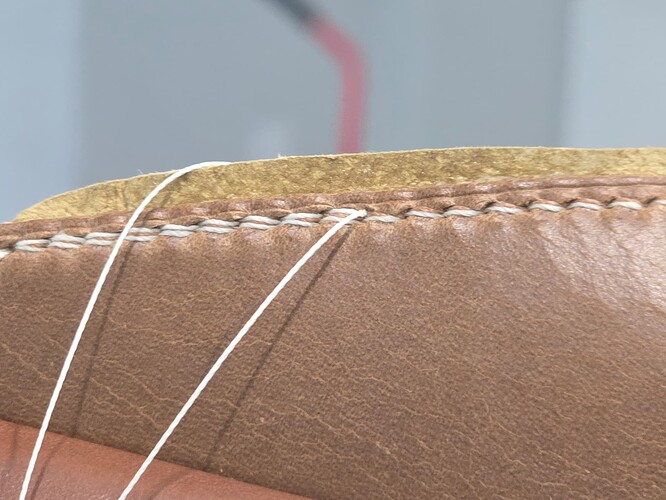

I continue to really enjoy closing my uppers by hand, a practice once known as “binding” that got killed off by Singer’s sewing machine. One of the fun parts of it has been finding and trying stitches that aren’t practical or maybe even doable by machine.

Thinking about it more systematically, what I’m looking for are stitches that:

- can’t be done by any common machine

- meet or beat the strength and durability of machine lockstitch or chainstitch

- create stitches that don’t look any like stitches made by machine

As a negative example, simple two-needle “saddle” or “shoemaker” stitch wouldn’t count, because while it can’t be done with any common machine and beats lockstitch on strength in many cases, it doesn’t look that different from machine lockstitch. Even if you pierce slanted holes and twist the threads for a highly slanted look on one side, lockstitch machines can get much the same effect with relatively large elliptical-point needles and relatively narrow thread.

However, there are some stitches that qualify:

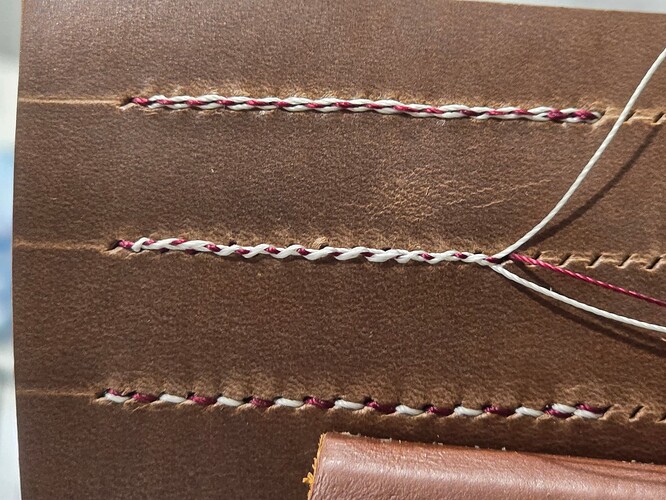

- saddle stitch with different color threads, top and bottom

This gives straight stitch in alternating colors. - saddle stitch with alternating stitch lengths, especially also with different color threads

I did these on my third pair and am still really happy with the effect. - most composite stitches

- single threaded saddle stitch

- double threaded saddle stitch

- twisted double threaded saddle stitch

AKA “Goyser”, “spinning”, “Norwegian” - single whipped saddle stitch

- double whipped saddle stitch

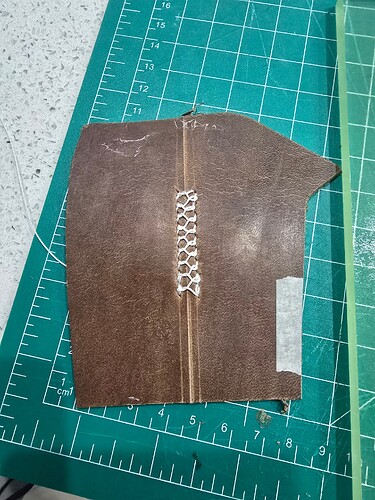

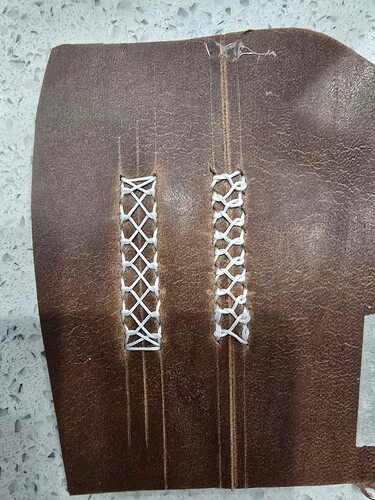

- many complex bar tack styles

I’d like to find some more!

One promising direction I have in mind is to riff on the theme of composite stitches. Sewing by hand, there’s nothing stopping us from looping other things in there, like beads or fibers like piteado.

Way back when, I also did some experiments criss-crossing stitches across multiple lines for Celtic knotwork-like effects. A number of these patterns met all my criteria, but none of them really caught my eye at the time.